Cognex | Machine Vision and Barcode Readers

Cognex vision, barcode reading, and logistics products make it easy to deploy, maintain, and expand machine vision-powered solutions that ensure quality, cut costs, and improve results.

Machine Vision | Cognex

Cognex creates reliable, easy to use machine vision solutions built on decades of expertise in factory and warehouse automation projects big and small. With over 4.5 million systems …

In-Sight Machine Vision Systems | Cognex

What is a vision system? A vision system, also called a "vision inspection system", is a technology solution that enables industrial machines to "see".

Machine Vision and Industrial Barcode Reading Products | Cognex

Cognex vision software provides access to the industry’s leading vision tools in a format designed for any development need. All applications benefit from Cognex’s broad-based, industrial …

Categories of vision systems and the applications they perform

What are the main types of vision systems? While machine vision systems offer a wide range of features and options, there are three main categories to consider.

In-Sight 8000 Vision Systems - Cognex

As the world’s smallest, stand-alone vision system, the In-Sight 8000 series offers a range of monochrome and color vision systems in resolutions from 0.3MP up to 5MP.

In-Sight 3800 Vision System - Cognex

With twice the processing power of previous vision systems, the In-Sight 3800 offers ultimate performance for any manufacturing application. Fast tool speeds keep pace with your …

In-Sight Vision Suite Software - Cognex

In-Sight Vision Suite is embedded with a full library of vision tools, including industry-proven algorithms and innovative AI technology. These tools can be used individually or combined to …

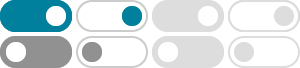

Vision Sensors - Cognex

Vision sensors are a type of automated solution that solve simple error-proofing applications. Typically, they perform a single function at a time, such as binary classification, defect …

Cognex AI | Cognex

High-performance vision system delivers high speed, resolution, accuracy, and flexibility for advanced manufacturing challenges. Combines rule-based tools and edge learning …